Manual handling risk assessment is crucial for identifying and mitigating risks associated with lifting‚ carrying‚ and moving objects. It ensures a safer workplace by evaluating tasks‚ loads‚ and environments to prevent injuries and musculoskeletal disorders‚ aligning with legal requirements and promoting employee well-being.

1.1 Importance of Manual Handling Risk Assessment

Manual handling risk assessments are essential for reducing workplace injuries and ensuring compliance with legal standards. They help identify hazardous tasks‚ evaluate risks‚ and implement controls to protect employees from musculoskeletal disorders and injuries. By assessing tasks‚ loads‚ and environments‚ employers can prevent harm‚ enhance safety‚ and promote a healthy workforce. Regular assessments also support legal compliance‚ reduce financial losses from injuries‚ and improve overall workplace efficiency. They empower employees to recognize risks and adopt safe practices‚ fostering a culture of safety and responsibility. Ultimately‚ manual handling risk assessments are a critical tool for safeguarding employee well-being and maintaining a productive‚ injury-free work environment.

1.2 Brief Overview of Manual Handling Risks

Manual handling risks arise from tasks involving lifting‚ carrying‚ pushing‚ or pulling‚ which can lead to injuries like strains‚ sprains‚ and musculoskeletal disorders. These risks are influenced by factors such as the weight and size of the load‚ the posture required‚ and the frequency and duration of the task. Environmental conditions‚ like uneven surfaces or limited space‚ further exacerbate these risks. Employees in sectors such as logistics‚ healthcare‚ and manufacturing are particularly vulnerable. Identifying these risks is crucial for implementing effective controls and ensuring a safe working environment. Regular assessments help mitigate these hazards‚ protecting both employees and employers from the consequences of work-related injuries.

Legal Requirements for Manual Handling Risk Assessment

Manual handling risk assessments are mandated by the Manual Handling Operations Regulations 1992‚ requiring employers to evaluate and mitigate risks to prevent musculoskeletal disorders.

2.1 Manual Handling Operations Regulations 1992 (as amended)

The Manual Handling Operations Regulations 1992 (as amended) are a cornerstone of UK health and safety law‚ specifically addressing manual handling risks. These regulations mandate employers to assess and reduce risks associated with manual handling tasks that could lead to injury. Employers are required to identify tasks involving lifting‚ lowering‚ pushing‚ pulling‚ or carrying that may pose a risk of musculoskeletal disorders. The regulations emphasize the need to avoid hazardous manual handling wherever possible and‚ where not feasible‚ implement control measures to minimize risk. Employers must also provide training to employees on safe manual handling practices. Non-compliance can result in legal penalties and increased workplace injuries‚ making adherence to these regulations critical for organizational compliance and employee well-being. These legal standards ensure proactive management of manual handling risks in the workplace. Employers must remain vigilant in applying these regulations to foster a safer work environment. Regular reviews and updates to risk assessments are essential to align with evolving workplace conditions and legal expectations. By adhering to these regulations‚ organizations can significantly reduce the likelihood of work-related musculoskeletal disorders and promote a culture of safety. The regulations also serve as a framework for conducting thorough risk assessments‚ ensuring that all potential hazards are identified and mitigated effectively. Overall‚ the Manual Handling Operations Regulations 1992 (as amended) play a pivotal role in safeguarding employee health and ensuring legal compliance for businesses. The regulations underscore the importance of a structured approach to manual handling risk management‚ benefiting both employers and employees alike. This legal framework is instrumental in creating a safer and healthier workplace environment.

2.2 Employer Responsibilities in Conducting Risk Assessments

Employers are legally obligated to conduct thorough manual handling risk assessments to protect employees from work-related injuries. Their responsibilities include identifying tasks that involve manual handling‚ assessing the associated risks‚ and implementing appropriate control measures. Employers must evaluate factors such as the task’s demands‚ the individual’s capabilities‚ and environmental conditions. They are also required to consult with employees and their representatives to gather insights and ensure the assessment’s accuracy. Employers must ensure that control measures‚ such as engineering solutions or administrative practices‚ are implemented and communicated effectively. Regular monitoring and review of risk assessments are essential to maintain compliance and adapt to changing workplace conditions. Employers must also provide training and ensure employees understand and follow safe manual handling practices. Failure to meet these responsibilities can lead to legal consequences and increased workplace injuries. Employers must prioritize proactive risk management to safeguard employee health and well-being. These responsibilities highlight the critical role employers play in preventing manual handling-related injuries. By fulfilling these duties‚ employers contribute to a safer and more compliant work environment. Regular updates to risk assessments ensure ongoing protection for employees. Employers must remain committed to continuous improvement in manual handling safety.

Conducting a Manual Handling Risk Assessment

Conducting a manual handling risk assessment involves systematically identifying‚ evaluating‚ and controlling risks to prevent injuries. Employers must assess tasks‚ consider individual capabilities‚ and implement safe practices.

3.1 Identifying Hazardous Manual Handling Tasks

Identifying hazardous manual handling tasks is the first step in a risk assessment. These tasks involve lifting‚ carrying‚ pushing‚ or pulling loads that could cause injury. Factors such as the weight of the load‚ awkward postures‚ repetitive movements‚ and insufficient rest periods contribute to the risk. Employers should observe workers performing tasks‚ consult with employees‚ and review incident reports to pinpoint hazardous activities. Tasks that require excessive force‚ are performed in confined spaces‚ or involve unstable loads are particularly risky. Documentation of these tasks is essential for further evaluation and implementation of control measures. Early identification ensures that risks are addressed proactively‚ reducing the likelihood of musculoskeletal disorders and workplace accidents.

3.2 Evaluating the Risk of Injury or Musculoskeletal Disorders

Evaluating the risk of injury or musculoskeletal disorders involves analyzing the likelihood and potential severity of harm from identified manual handling tasks. This step uses observations‚ measurements‚ and assessment tools to quantify risks. Factors such as task frequency‚ duration‚ and individual worker capabilities are considered. The evaluation determines whether the risk is low‚ medium‚ or high‚ guiding prioritization of control measures. Tools like the Manual Handling Assessment Chart (MAC) or the Snook Push/Pull/Carry Tables can aid in quantifying the risk. Documentation of findings is critical for developing strategies to mitigate hazards and protect workers from musculoskeletal disorders. This evaluation ensures targeted interventions are implemented to reduce workplace injuries.

Key Factors in Manual Handling Risk Assessment

Key factors include task demands‚ individual capabilities‚ load characteristics‚ and environmental conditions‚ as outlined in the TILE principles‚ to identify and mitigate manual handling risks effectively.

4.1 Task‚ Individual‚ Load‚ and Environment (TILE) Principles

The TILE principles are fundamental to manual handling risk assessments‚ focusing on four key elements: Task‚ Individual‚ Load‚ and Environment. By evaluating these factors‚ risks can be systematically identified and mitigated. The Task involves analyzing how the work is performed‚ including repetitive movements‚ awkward postures‚ and duration. The Individual considers personal capabilities‚ such as physical fitness‚ strength‚ and health conditions. The Load examines the weight‚ size‚ and stability of the object being handled. Finally‚ the Environment assesses workplace conditions like flooring‚ lighting‚ and space constraints. By applying TILE‚ organizations can develop targeted strategies to reduce musculoskeletal risks and create safer working conditions. This structured approach ensures comprehensive risk management.

4.2 Assessing the Combination of Risk Factors

Assessing the combination of risk factors in manual handling is crucial for identifying how multiple risks interact. This approach recognizes that individual risks‚ such as heavy loads or awkward postures‚ may exacerbate each other when combined. For example‚ lifting a heavy object in a confined space increases the likelihood of injury due to limited movement and poor posture. Employers should evaluate how task demands‚ worker capabilities‚ and environmental conditions intersect to create hazards. By prioritizing tasks with the highest combined risks‚ organizations can implement targeted controls‚ reducing the overall likelihood of musculoskeletal disorders. This holistic evaluation ensures that no single risk factor is overlooked‚ promoting a safer working environment. Effective risk assessment requires a thorough understanding of how these factors interact.

Control Measures for Manual Handling Risks

Implementing control measures is essential to minimize manual handling risks. This includes engineering solutions‚ ergonomic adjustments‚ training‚ and administrative practices. Proper lifting techniques‚ mechanical aids‚ and regular monitoring further reduce risks.

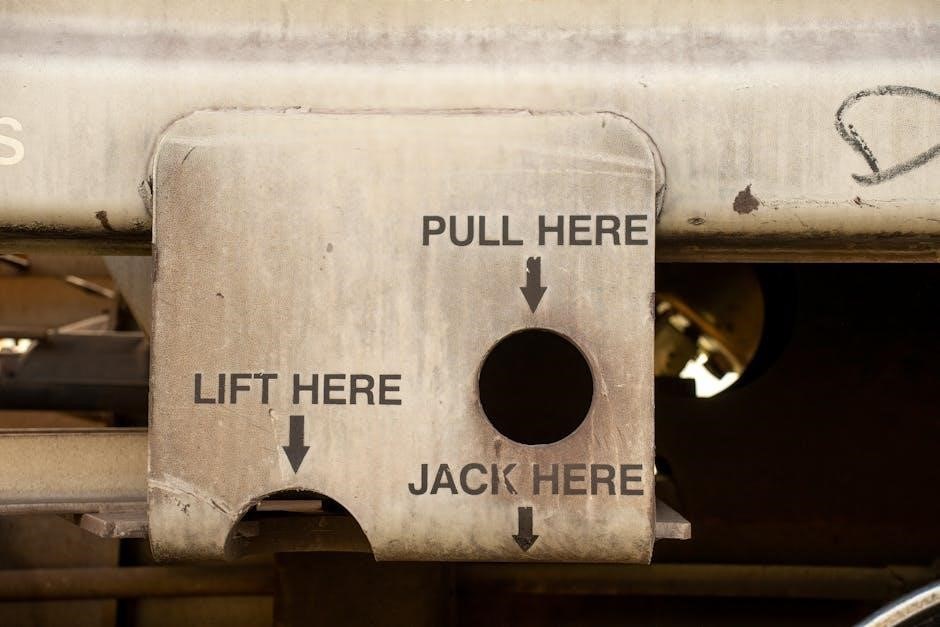

5.1 Engineering Controls to Reduce Manual Handling Risks

Engineering controls are physical changes to the workplace or equipment that reduce manual handling risks. Examples include mechanical aids like conveyors‚ hoists‚ or automated systems. These solutions minimize the need for manual lifting‚ lowering‚ or carrying. Ergonomic adjustments‚ such as height-adjustable workstations or tools with handles designed for better grip‚ also fall under engineering controls. Implementing these measures ensures tasks are safer and more efficient. Regular maintenance of equipment is crucial to sustain their effectiveness. By prioritizing engineering controls‚ employers can significantly reduce the physical demands on workers and lower the risk of musculoskeletal injuries. These controls often align with legal requirements‚ such as the Manual Handling Operations Regulations 1992.

5.2 Administrative Controls and Safe Work Practices

Administrative controls involve implementing policies and procedures to minimize manual handling risks. These include task rotation‚ job rotation‚ and adjusting workloads to reduce repetitive or strenuous tasks. Safe work practices‚ such as proper lifting techniques and load management‚ are essential. Employers should establish standard operating procedures (SOPs) for manual handling tasks‚ ensuring employees follow guidelines. Training and supervision are critical to ensure compliance. Administrative controls also include monitoring work patterns and providing regular rest breaks. These measures complement engineering controls by addressing workplace organization and employee behavior. By implementing administrative controls‚ employers can create a safer work environment and reduce the likelihood of injuries or musculoskeletal disorders. Regular reviews of these controls ensure their ongoing effectiveness.

Training and Employee Awareness

Effective training and employee awareness are crucial for minimizing manual handling risks. Regular training ensures employees understand proper techniques and safety protocols‚ reducing injury risks and improving compliance.

6.1 Importance of Manual Handling Training

Manual handling training is essential to reduce workplace injuries and ensure compliance with legal requirements. It equips employees with proper lifting techniques‚ load assessment‚ and hazard identification skills. By understanding the risks associated with manual handling‚ workers can adopt safer practices‚ minimizing the likelihood of musculoskeletal disorders. Training also fosters a culture of safety‚ encouraging employees to take responsibility for their actions and report unsafe conditions. Employers benefit from reduced absenteeism‚ improved productivity‚ and lower insurance costs. Regular training ensures employees stay updated on best practices and industry standards‚ making it a critical component of an effective risk management strategy. Tailored training programs address specific workplace tasks‚ ensuring relevance and effectiveness in mitigating manual handling risks.

6.2 Dynamic Risk Assessment Using TILE Principles

Dynamic risk assessment using the TILE principles is crucial for ensuring safety during manual handling tasks. TILE stands for Task‚ Individual‚ Load‚ and Environment‚ providing a framework to evaluate risks in real-time. The Task involves analyzing the nature of the work‚ such as lifting techniques and movement patterns. The Individual considers the worker’s physical capabilities and health status. The Load examines the weight‚ size‚ and stability of the object being handled. The Environment assesses the workspace‚ including obstacles‚ floor conditions‚ and lighting. By continuously monitoring these factors‚ workers can adapt their actions to mitigate risks as conditions change. This proactive approach enhances safety‚ reduces injury risks‚ and ensures compliance with manual handling guidelines. Regular training in dynamic risk assessment using TILE principles is essential for maintaining a safe working environment.

Tools and Templates for Manual Handling Risk Assessment

Various tools and templates simplify manual handling risk assessments‚ such as risk assessment forms‚ hazard checklists‚ and software solutions. These tools help identify and evaluate risks systematically.

7.1 Manual Handling Risk Assessment Templates

Manual handling risk assessment templates provide structured frameworks to identify‚ evaluate‚ and control risks. They include sections for task descriptions‚ risk factors‚ and control measures. These templates ensure consistency and compliance with legal standards. Many organizations offer downloadable templates‚ such as the UK’s Health and Safety Executive (HSE)‚ which provide step-by-step guidance. Templates often cover the TILE principles‚ helping assess tasks‚ individuals‚ loads‚ and environments. They also include risk scoring systems to prioritize actions. Customizable templates cater to specific industries‚ like healthcare or manufacturing. Regular updates ensure alignment with evolving regulations. Using these templates streamlines the assessment process‚ making it easier to document and communicate findings to employees and stakeholders. They are essential tools for proactive risk management and injury prevention in workplaces.

7.2 Checklists for Identifying Hazardous Tasks

Checklists for identifying hazardous manual handling tasks are invaluable tools for ensuring workplace safety. These checklists typically include questions or criteria to evaluate tasks based on factors like repetition‚ force‚ posture‚ and duration. They often align with the TILE principles‚ focusing on task‚ individual‚ load‚ and environment. Common elements include assessing the frequency of tasks‚ the weight or size of loads‚ and the working environment’s layout. Checklists also consider individual worker attributes‚ such as physical capabilities and prior injuries. By systematically identifying high-risk tasks‚ employers can prioritize interventions and reduce injury risks. Many checklists are available in PDF formats‚ making them easy to download and use. They are practical resources for compliance with legal requirements and fostering a safer workplace culture.

Case Studies and Real-World Examples

Real-world examples from industries like healthcare and manufacturing illustrate how manual handling risk assessments reduced injuries by implementing ergonomic solutions and targeted training programs‚ enhancing overall workplace safety and efficiency.

8.1 Examples of Hazardous Manual Handling Tasks

Hazardous manual handling tasks are common in various industries and often involve lifting‚ carrying‚ pushing‚ or pulling heavy or awkward loads. For instance‚ healthcare workers frequently lift patients‚ which can lead to musculoskeletal disorders. In manufacturing‚ employees may manually handle heavy equipment or materials‚ increasing injury risks. Retail workers often lift boxes or stock shelves‚ while construction workers manage heavy tools and materials. These tasks are hazardous due to factors like repetitive motions‚ awkward postures‚ or excessive force. Identifying such tasks is crucial for conducting effective risk assessments and implementing controls to prevent injuries. Real-world examples highlight the importance of addressing these risks to safeguard employee health and productivity.

8.2 Lessons Learned from Manual Handling Risk Assessments

Manual handling risk assessments have taught organizations the importance of proactive strategies to minimize injuries. A key lesson is the need for regular assessments to identify high-risk tasks early. Many workplaces have learned that employee training significantly reduces incidents‚ as it equips workers with proper techniques. Additionally‚ involving employees in the assessment process fosters a safety-first culture. Organizations have also discovered that implementing control measures‚ such as mechanical aids or task redesign‚ can drastically lower injury rates. Another critical takeaway is the value of monitoring and updating assessments to adapt to changing work environments. These lessons emphasize the importance of a structured approach to manual handling risks to protect worker health and productivity;